LINKS TO FEATURED PAGES:

![]() TRIUMPH

Contents page > Triumph TR3 tool roll contents

TRIUMPH

Contents page > Triumph TR3 tool roll contents

|

This is an illustrated discussion of what I have learned about the TR2 through TR3B tools. There seems to be some controversy about what tools were supplied with which car. I suspect that some tools may have been left out or substituted when the factory ran out of stock on hand. Also the tool manufacturers made some changes to their products over time. Then there were original owners who may have lost, added or substituted tools in their kit. So there are lots of opportunities for variations, some by the manufacturer, some by the Triumph factory and some by previous owners. However there is a set of tools that are generally accepted as original and normally supplied. Normally supplied are a tool roll, jack, jack ratchet, starting handle, combination tool, screwdriver, adjustable spanner, pliers, grease gun, three open end spanners, two box or tube spanners, bar for box spanners, feeler gauge, distributor tool, coach key and a valve stem remover. Disk wheel equipped cars also got a wheel brace and a tommy bar for removing the hub caps. TRs equipped with spoke wheels got a knock off hammer. After TS32585 a headlamp removal tool was added to the tool. Tyre irons appeared in TR2 and 3 tool kits but normally not in TR3A rolls. Most of the tools supplied in TR2 - 3B tool rolls were made by T.Williams. They will have the T.Williams logo and a "Made in England" label. The T.Williams logo is a "T" over a "W" inside a circle. The logo and made in England label are raised letters. Except for the grease gun, jack & handle, TR2 tools tended to be finished in black oxide while later sets were finished in clear cadmium

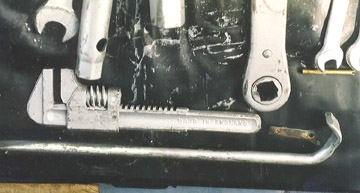

This picture shows the adjustable spanner, and the Tommy bar for removing hubcaps. The valve stem removal tool can be seen at the end of a fixed spanner. The finish of the steel tools is cadmium. The finish on the jack ratchet handle should not be cadmium. Tool rollsThere were two versions of tool rolls. The TR2 and early TR3s had a plastic coated jute roll. The later TR3s and newer TRs had a plastic tool roll. This roll is black in all but the TR3B. TR3B rolls tend to be a peach like colour. Some may have been black. Adjustable spannerThis is a seven inch adjustable spanner that looks basically like a pipe wrench. There were several manufacturers but T. Williams was by far and away the most common manufacturer of adjustable spanners in TR tool rolls. There were slight variations in the spanner over the years. Adjustable spanners supplied with very early TR2 black oxide. All others finished in clear cadmium. Feeler gaugeThis gauge consists of three feeler leaves riveted together at the center. This allows them to rotate in relation to each other. One leaf is 0.024 inches thick, rectangular 2-5/8th inches long by 5/8ths inch wide. The other two feeler leaves are tapered and rounded at each end. One is 0.010 inch thick, the other is 0.012 inch thick.

ScrewdriverA wood handle screwdriver is included in the tool kits. The natural Beach wood finish handle is usually round with a ball shaped end. There is a chrome cap covering the bottom of the handle at the base of the shaft. There were a couple of different shaped shafts used. Open end spannersNormally three were provided. In later TR3As sometimes as many as five were provided. The three standard sizes are: 3/8 X 7/16 AF, 1/2 X 9/16 AF and 5/8 X 3/4AF. TR 2 and early TR3 spanners had a black oxide finish with clear metal at the ends. Later were clear cadmium finished. Triumph used the Superslim models of spanner manufactured by T. Williams. The wenches had Made in England on one side and Superslim on the other side. Both sides use raised letters.

The black oxide finish of this kit marks it is a TR2 or early TR3 tool kit. The plastic tool roll is likely unoriginal as most if not all black oxide finished tool sets came in the early plastic coated jute tool rolls. The screwdriver is not the original type. The grease gun is the Tecalimit GB1801 model with blue hammerite paint. Grease gunThe grease gun appears to be a capped tube with a narrow pipe and fitting at one end. The pipe is spring loaded and injects a squirt of grease then the tube is pressed down. A plunger type grease gun is common in British car tool rolls but was evidently never used in early Triumphs. Enots manufactured a blued #1 grease gun that appeared in early TR2 tool rolls (a few black ones were used). This has an externally sprung nozzle. Later TR2's used enots #1d which is the same in all respects as the #1 except that it is 1inch (2.5cm) longer in the body. Tecalimit GB2801 grease guns were commonly used in very late TR2 through TR3B tool kits. The finish was usually blue hammerite paint, but there were some bronze metallic panted ones. PliersThe pliers are standard slip joint gas pliers. Early pliers had the black oxide finish. Later pliers had a clear cadmium finish. Look for the T. Williams logo and " made in England" labels.

Cadmium plated tool set for a steel wheel equipped Triumph. Notice the tommy bar and the wheel brace. The jack is the late style Smiths speedy jack with the bolted on lift hook. The Lucas distributor tool can be seen to the right of the adjustable spanner's base. The feeler gauge is just above the distributor tool. The jack handle can be seen along the top. Jack and handleThere are three models of jacks used in the TR2 through TR3B. Very early TR2s used a jack with an external thread and built on handle. All the other TR2 through 3B Triumphs were equipped with a Smiths jack. The early version had the lift hook welded onto the body. The late style had the lift hook clamped and bolted to the outer tube. The earlier jack came in black or an orange red colour. The late jack only came in the orange red colour. The jack base was black oxide on both models. The square top was ether black oxide or cadmium plated. Early jacks came with TR2 and TR3s. The late style jack started being provided sometime during the TR3 production run and was provided with TR3A and 3Bs. The jack handle is a ratchet design. There were two general types of handles. One had a smooth handle. The other had a indented centre handle and came with late TR3A and TR3B Triumphs. The handles came in black oxide, gunmetal blue,black or red paint. Wheel braceThe wheel brace was provided with Triumphs equipped with steel disc wheels. The colour is black. The inside of the nut socket is blue hammertie paint. Tyre IronsStandard Dunlop style finished in black oxide. Provided with TR2 and TR3 models. Unlikely to be found in TR3A models. Tommy barThis is a pry bar that was provided with Triumphs equipped with steel disc wheels. Early versions had a black oxide coating. Late TR2 and newer models had a clear cadmium finish. They were provided to remove the hub caps. Knockoff hammerProvided only with wire wheel equipped Triumphs. Manufactured by Thor. Hammer had copper ends on all but the early TR2s. Early TR2 Thor hammers had one leather end. A word of caution. The copper hammers can distort the knockoffs. Lead hammers deform themselves and not the knockoffs. These are unoriginal but treat your knockoffs better.

Early jute tool roll, early black oxide tool finish, early style Smith jack and late style jack handle. Pliers are not original. Grease gun while contemporary is not the original style. The rod between the open spanners and the pliers is inserted into side holes in the box spanner to turn the box spanner. Black finish starting handle along the top. Starting handleProvided with all models. Black or orange red paint. Box or tube spannerTwo were normally provided. Finish black oxide supplied with early TR2. Finish clear cadmium with later models. One spanner is a 6 inch long spark plug wrench. The other is 7 inches long. Tube spanners have holes in side for steel tubular rod. Distributor toolMade by Lucas. Narrow end is a screw driver. Has a blued feeler gauge riveted to the screw driver section. Used to set point gap. Valve stem toolUsed to remove valve stems to deflate tyres. Brass cylinder knurled at one end for grip. Notched at the other end. TR3B valve stem tools may be plastic. Coach key'T' handle tool for opening the bonnet, spare tyre cover, early boot lids and to attach side curtains. Don't drive a TR without one. Headlamp rim toolProvided after TS32585 when the snap in head lamp rims started being used. Five inch long 'L' shaped sheet metal.

|

|

© 1997 - 2017 TeriAnn Wakeman. All rights reserved.