This is the saga

of TS75519L's rebuild. It is a continuation of this car's known

history . It tells of a car rebuild innocent learning about

almost everything that can go wrong. It is a tale of tenacity

in the face of adversity proving that a car can be completely

rebuilt on dirt without a garage in spite of the efforts of trained

professionals. It is also a tale that proves the law of the innate

cussedness of inanimate objects.

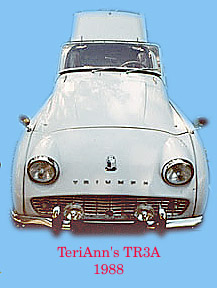

A picture of my TR3 taken before the beginning of

the rebuild. The shinny Chevy white paint hid fillers over severe

rust. Bubbles had been appearing in the paint over the previous

year.

I took my car off the road for a "freshening up" in January of

1989. During the previous October Triumphfest I self judged her

and decided she was a few points shy of the bronze funcourse award.

I thought that since I was going to have to rebuild the engine

I might as well take care of the steering and freshen up the car

well enough to bring her into a condition good enough for a solid

silver and maybe within reach of the gold funcourse award.

My freshening up goals were simple:

- rebuild engine,

- rebuild front steering,

- repaint the black engine bay and the black boot area to match

the body colour,

- install a new interior,

- replace the wiring harness,

- sand down the body where paint bubbles came up, remove any

rust and spot paint it.

I calculated that I could have the job done in about 5 months

and be back on the road sometime in June to spend the rest of

the summer touring with the Triumph

Travelers Sports Car Club. Like I said I have never done this

before.

I first removed the interior that I was planning

to replace. The fuel tank was removed and sent to a radiator shop

to be boiled out and had deep rust areas patched.

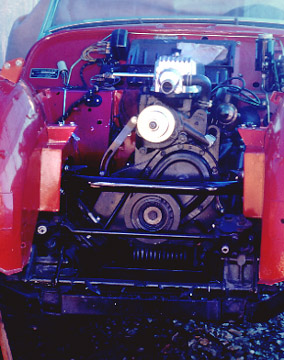

Early during the rebuild. The front clip, engine

and gearbox have been removed. The rotted out battery box has

been removed. I was right on schedule

Everything I took off was badly worn. When I stripped the interior

I discovered that the car was signal red from the factory and

that the floor was coated with fiber glass under the paint and

that there were great gaping rust through holes on the floor under

the fiberglass. I decided that meant new floor panels and that

I could have a body shop install them and still meet my deadline.

I removed the doors to make the work on the interior easier.

The door metal around the hinges were badly fatigued and there

were fatigue cracks going through the metal on at least two sides

of each hinge on both doors. Also the bottoms were severely rusted

with a lot of rust through holes. I located a pair of good condition

used doors for a reasonable price through the British

car e-mail list and decided to replace the doors instead of

having them completely rebuilt. It would save a lot of time and

maybe I could still make schedule.

The fuel tank area had lots of rust, some of it very severe with

small rust pit holes going all the way through. All the badly

rusted areas were under the felt pads that sit between the fuel

tank and the body. I decided to remove all traces of rust there

and weld the holes shut and build up the rust craters. Even though

no one would see it, I wanted it perfect.

The tank had several deep rust pits as well. I looked at several

used ones for possible replacement since new ones were not available.

They were all as bad or worse than mine where they had touched

the felt pads. I finally opted to have mine repaired. It was boiled

out and new metal was welded into place where the deep rust pits

were.

After I stripped the interior, I started on the front of the

car in preparation for the engine removal. The underside of the

front valance had some surface rust and a fiber glassed rust through

section on the underside. Well I could have the body shop weld

in some new metal where it is rusted through while they replaced

the floor panels.

The car has been stripped. All the body parts

are carefully placed so as not to damage the paint. The plan at

this time was to put the panels back on without repainting. I

knew by now the doors and floor needed replacing. by this time

my schedule had slipped about 2 months because of additional work

that needed doing.

I sanded down the lower front wing panels where rust was bubbling

up through the paint. More fiberglass over bad rust through areas.

I was getting a very bad feeling about this. I looked in the catalogues

and decided to purchase a pair of lower wing repair panels and

just replace the metal. This was going to cost a whole lot more

than I thought and take more time at the body shop. Maybe I could

rejoin the club tours in July or August.

The engine bay had been taken down to bare metal

primed and sealed. The new battery box was due to be added next.

At this time the plan was not to repaint the exterior.

With this many areas requiring repainting I decided it would

make sense to respray the entire body. Since I do not pay myself,

I decided to do a colour sanding of the body so I would not have

to pay the shop for it. I was sanding the rear of the prefect

looking rear valance and put my hand through the body. My heart

sunk down to my feet and I had the feeling that my feet were no

longer touching the bottom. I was definitely in the deep end of

the pool without swimming lessons.

I walked into the house, checked the Moss

Motor's catalogue and ordered a new rear valence on the spot.

I grabbed a bottle of ale, went back to the TR and sat there staring

at her. A sane person would put the car up for sale to an experienced

car restorer and look for another car at this point. But I had

almost three years of recent fond driving memories. Besides I

was never very good at this sanity thing.

I decided that all the paint had to come off just to see what

was lurking underneath. The freshening up project that had been

growing larger as each bit was removed had just now turned into

a genuine full blown complete restoration project . That meant

no club touring this year. With luck the car would be ready at

the beginning of the following touring season. I told you I had

never done this before and I was totally naive about how long

it takes to get things done... And how long it takes to learn

how to do the work and redo what I botched the first time.

There is a phrase used on the British car e-mail list and many

of the British marque e-mail lists that the original list has

spawned. The phrase is "shipfitter's disease". The person who

first defined it on the British car list in the spring of '89

defined it thus:

" A boat owner noticed that a light bulb was burned out in the

cabin and went to replace it. While replacing it he noticed that

the socket was cracked and decided to take care of it while he

was at it. After removing the fixture he noticed that the wiring

insulation was frayed. Since he already had the fixture off it

seemed like the easiest time to replace the frayed wiring. He

removed the wiring and exposed the wood underneath. He could clearly

see dry rot on the beam. Well since he already had the wiring

off... And before long, the boat was in dry dock undergoing a

complete refit because a light bulb burned out in the cabin."

This phrase was first coined on the British car e-mail list to

describe my freshening up project when the tales of woe were sent

out to the list by a disheartened woman looking for comfort in

the sight of a badly rusted TR that had looked pretty good.

Did I mention that I do not have a garage? I erected a pipe frame

over the car and hung a tarp over the frame. So all my work has

been done in the dirt or mud at outside ambient temperature.

Removing the Chevy white paint gradually exposed a severely rusted

TR3A. It looked like the previous owner wire brushed the rust

then covered it with fiber glass and paint. A trick I could not

repeat and feel good about the car. Maybe that is why he sold

it before even finishing the project? At least he felt bad enough

to sell her well below the current market price for what she appeared

to be and closer in value to what she was under the paint. At

the price I paid I did not feel ripped off, and I did get almost

3 years of driving fun out of her. That driving time had me hooked

and I wasn't about to let a body that looked like swiss cheese

keep me from driving her some more! Like I said, I was never very

good at this sanity thing but I am fairly good at rationalizing.

After I stripped the car she went into the body shop for professional

help. I decided to leave the frame alone because it was in excellent

condition. I also decided to leave the body on the frame. I could

not see any reason for removing it other than to be able to say

I did a frame off restoration. And I had heard too many stories

of bodies going out of alignment when handled off the frame. Besides

it was easier to move with wheels under it.

My TR3A had the wrong bonnet so I purchased the correct post

TS-60000 bonnet. The boot lid had a lot of rust through holes

covered by fiberglass. I picked up a very good condition used

boot lid to replace the original. The front wings were rebuilt

using new lower wing panels. The car got new floors, inner and

outer sills and rear valance. Several sections of Swiss cheese

like rusted through metal were cut out and replaced with new metal.

The dog legs behind the doors were rebuilt with new metal. Every

bit of rust was removed from the car. Previously hidden damage

around the base of the windscreen was repaired.

Counting the "new" doors I estimate that between 60 and 70% of

the car now was made of new metal or replaced used rust free body

panels

Needless to say this cost me a chunk of change. So much for my

cheap car. I did not have enough money to get the car painted

at that time so I had the car primed and sealed, and an undercoat

added on the underside to help guard against moisture damage then

brought her home for more work. Meanwhile my first and second

target completion dates had slipped into remote history and I

had given up on the concept of a completion date.

After the car came home from the body shop I tackled the suspension

and steering. When I removed the front coil springs I discovered

that one was an original and the other was the taller factory

replacement spring. The taller spring was supposed to be installed

with the aluminum spacer removed. It still had the spacer installed.

This meant very different front spring tensions and lengths.

The trunions were very badly worn and the arm of one was sheared

off where the fixing bolt would have been. The trunions were so

badly worn that they wobbled past the steering stops. The various

bushings and joints had seen better days too. The worm gear was

showing some wear and the bearings in the steering box were not

in good condition. It looked like it had run dry for a long time.

When I disconnected the arms to the rear shock absorbers I discovered

that they were there solely for ballast. The arms flopped down

to the bottom position without any resistance. No wonder the car

handled so poorly.

I replaced the springs with the factory competition style, the

front shocks with new SPAX adjustable shocks. New trunions, bushings,

tie rod ends and ball joints were installed. I sent my steering

box to The Roadster Factory to have it rebuilt with new bearings

and worm & peg. New brake calipers went on the front. Apple

Hydraulics rebuilt the rear shocks using heavy duty valves.

When I was driving the TR, I was just starting to get into auto

crossing so I decided I wanted to build the engine with a bit

more power and strengthen the weak areas. About that time I met

Ken Galanders, learned about the competition engine stuff he was

selling and got carried away.

The insides of engines need to be very clean. Working outside

in the dirt I decided that I did not have the facilities to rebuild

the engine and keep it clean.

There is a car repair hop near my home called "Greg Solo's Engine

Room". Greg Solo is into building and racing Morgans that have

the same Triumph engine that my TR3 has. I decided to farm the

rebuild out to the Engine Room and have it done right by TR race

engine experienced professionals. I ordered the engine built to

certain specifications and provided a lot of special parts that

I purchased from Ken Galander's company, British Frame and Engine.

About this time I made a "dumb" decision. I just LOVE the look

of multiple DCOEs. For years I have WANTED a car with DCOEs. I

just HAD to have a set of DCOEs. I say this was a dumb decision

for three reasons. One, SUs are simpler, I know how to get them

to work and I have a pair. Two, SU's work very well on a TR engine.

Probably better than the Webers under most conditions. And three,

I can not auto cross in a stock class with DCOEs.

So I made the decision to have a set of Webers for street driving

and touring and keep my SUs for auto crossing. The plan was to

switch between carbs, manifolds & linkage depending upon what

I was doing. There was no logic here. Just pure & simple desire.

So I ordered a new pair of DCOE45s built down to 42 specifications.

When I got enough money ahead I asked my local automotive paint

store owner for recommendations for a local company that did a

good job of painting at a reasonable cost. The recommended Felton

Auto body.

I had the car flatbeded over for them to do stage one of the

painting. Stage one was to sand, reprime and paint the interior

of the car. This included engine bay, boot, spare tyre compartment,

fuel tank area, underside of the front valance, bonnet, boot,

spare tyre compartment lid, door interiors and painting all the

body and wing overlap seams.

The painter complained that the "mud" applied by the body work

company to even out manufacturing panel waves was way too thick.

He said that it would probably crack from vibration. So I got

to pay extra for the new company to undo some of the work from

the old company.

When the stage one painting was completed I brought the car home

and plumbed the new hydraulic system. I have lived through four

hydraulic failures caused by pinhole rust through leaks in the

steel tubing. On the first, I pulled a James Dean imitation and

bailed out of my car just before it went over a cliff. So the

Triumph got stainless steel brake lines.

I installed the refinished instrument panel, fuse box, solenoid,

voltage regulator and the wiring harness. Next the refurbished

and newly painted fuel tank was installed. I installed the newly

rebuilt steering box and discovered that the steering was very

hard. I disconnected the rods and isolated the problem to my new

steering box. So it want back to The Roadster Factory for a warranty

fix. It came back working properly and I installed it with no

problems.

I got the newly rebuilt engine back form the Engine Room, mated

it with the transmission and installed it into the car. The radiator

and front valance went on. I went to hang the doors and discovered

that the door openings were about 1/4 inch too short.

I went back to the company who did the body work. The person

who did all the work had been fired shortly after finishing with

my car because the owner discovered that he was coming into work

on Heroin. He discovered this after a number of cars the person

worked on came back because of poor work. The owner took back

the car to lengthen the center section 1/4 inch. I got the car

back about a month later with the doors hung.

I put the wings on with a couple of bolts and brought the car

back to the paint shop to have the outside painted and some scratches

I made installing the engine repainted. While I was installing

the engine & other major interior stuff and having the car

lengthened, the paint shop I was working with had gotten into

financial problems. A partner estimated a number of jobs low,

emptied the company bank account and left. The remaining partner

was loosing money doing the jobs that were under estimated. I

had to prepay for my paint job just so he could purchase paint

and keep the electricity on to do the painting. I paid for a colour

coat and to come back after the car was assembled for last touch

ups and to have the car colour sanded and clear coated.

The car got painted and flatbeded home. I mounted the wings,

replaced the old worn crooked wire wheels with new Dayton chrome

wheels & splines. I discovered that the new stone guards do

not fit properly to the leading edge of the rear wings. A call

to The Roadster Factory confirmed that the reproductions do not

properly fit. So I bent them and got them to fit.

Around this time a heavy storm with high winds collapsed the

roof over my TR. The only damage was a cracked windscreen and

a little chip of paint off a front wing. This provided me with

the opportunity to have a new windscreen installed and to rechrome

the stanchions.

As I continued assembly I discovered that my new door sill finish

panels didn't fit properly and had to grind them a little. I went

to mount my freshly painted bonnet and boot lid to discover that

the body shop did not make any trial fits so the fit is poor and

gaps are uneven. I went to install the newly rechromed and reglassed

windscreen and discovered that it would not fit properly with

the stanchion spacers installed. When the body shop repaired the

cowl damage they built the corners up too high and checked fit

of the windscreen without the meal sliders that go between the

windscreen and the body. The windscreen fits without the sliders.

I went back to the paint shop to see if they could redo the top

edges of the front scuttle and take care of a few other things.

The paint shop had closed down. I had a bunch of stuff still there.

The building owner had come through and sent a lot of stuff to

the dump including all my rear body cappings, the sticks for the

hood, scuttle vent and opening hardware and a few other bits that

needed painting. Luckily my hard top was sitting in the yard out

back and I was able to retrieve it. My prepaid colour sanding

and clear coat had disappeared along with the company.

At this point my morale was at a low point. I wanted to do it

right and have everything turn out perfect. I gave up on the project

for about a year. Meanwhile condensation from the rains &

mud had affected the finish of polished work under the bonnet.

My roommate's little dog urinated repeatedly on my new chrome

wheels and her cats were spraying there too.

I finally decided that I had to either finish the rebuild or

sell it. So I started hanging parts back on it. I added DOT 5

fluid to the hydraulic system and pressure bled it. Next day I

discovered that I had not tightened down a connection to the reservoir

and the DOT5 had leaked out. I was REAL glad I did not use DOT

4. The rear wheel cylinders started leaking a week later. The

system had new everything except rear cylinders. This is when

I leaned that you need to use all new rubber when you go from

DOT 4 to DOT 5.

Next came the mile stone of starting the engine for the first

time. I checked all the rocker arm gaps just to be sure, removed

the spark plugs, and squirted a little light oil into each cylinder

then poured half a quart of oil down the push rod tubes to be

sure that the lifters and cam lobes had fresh lubrication. I spun

the engine until I got oil pressure indicated on the gauge.

I added fuel, hand pumped it into the carbs, reinstalled the

spark plugs and fired the engine up. It wouldn't idle properly

but it ran and the oil pressure looked good. There was lots of

oil being fed to the rocker arm assembly. I replaced the cover.

As I was checking things over I noticed that the temperature was

getting high and the electric fan had not come on. I shut the

engine down and checked the fan circuitry. The circuit was OK

but the fan motor evidently died sitting out in the weather for

eight years.

I replaced the fan with a new one and took the car out for a

run. The carb linkage was set up wrong with the pedal sitting

WAY too high. The new starter motor stopped working during one

of my stops to check things out and the carbs were definitely

not running correctly.

Since I had four tube headers on the car, replacing the starter

motor means removing intake and exhaust manifolds. I was feeling

discouraged about how this project was going and just totally

lost the heart to continue. It seemed like no matter how hard

I tried, how pure my motives everything that could go wrong did.

Meanwhile, some exciting Land Rover events were coming up so

I just parked the TR and went out and played in the Land Rover

taking numerous long expeditions. Life was a lot more fun with

a car that worked and was reliable.

Finally during winter of late '98 I got back to working on the

TR after letting her sit under her shelter for over a year. I

was dismayed to discover that my new wheels, bumper, bumperettes

and head lamp rings were all rusting. I removed the starter motor

and checked it out. It turned fine on the bench. I finally located

the problem. I had a well painted engine block and a well painted

starter motor. The fixing bolts had flat washers that did not

dig into the paint. Basically the paint was insulating the motor's

ground return path from the grounded engine block. I removed the

paint from the mating surfaces and the motor worked fine. When

I reassembled the linkage I adjusted it for the proper pedal height.

I retorqued the head, reset the rocker arm gap and tried it again.

I was still having fuel system problems. I took her out and ran

out of gas a couple of miles away from home. My professionally

rebuilt fuel gauge did not work.

I got a gallon of petrol and headed back for home to have the

car stop with fuel starvation going up a steep hill. By this time

it was getting dark and I had just discovered that the car had

no tail lights. I called for a flat bed tow home.

Next day I cleaned out a very dirty sediment bowl, changed a

clogged fuel filter & added fuel. I was back to where I was

before the last drive.

I checked the wiring and noticed that all the red wires went

to lamps. The wire from the switch required an inline fuse and

did not come with the wiring harness. I didn't notice that when

I was connecting the harness. I added a fuse line between the

side lamp switch position and the red wires. I had tail lights

and gauge lights. All the lamps needed was a source of voltage.

Ooops.

I checked my fuel gauge. It worked before I took the car apart.

It went out with all my gauges to be rebuilt and refinished professionally.

When I first put petrol in the fuel tank I noticed that the gauge

only went up about half way. The problem was not in the sender.

So I sent it back. I reinstalled it when it returned.

Now it doesn't work at all. One lead has 12V. The other rings

out to go directly to the sender unit. The sender unit ground

is OK. The sender unit float is OK and the resistance changes

as the float arm raises & lowers. I looked closely at the

gauge It reads empty when the sender is disconnected. When it

is connected (with fuel in the tank) the gauge pins to the less

than zero stop. Fuel gauges are thermal and not polarity dependent.

I think the company replaced the guts of my gauge with one that

works in the opposite direction. It is now on my list of things

to take care of. A third time.

I took the car out on a couple of short runs to identify and

work out additional problems. On the second run the car stopped.

I determined that there was no fuel going to the fuel pump but

there was fuel in the tank. When I disconnected the fuel line

at the pump nothing came out. The car was flat bedded home again.

Next day I removed the fuel tank and gave it a through internal

cleaning with a hose. Lots of sand, grit, a piece of bark, some

dead sow bugs, a spider web and other unknown stuff came out.

So much for my tape covered inlet while all the final body work

was going on. I drained the tank and dried the interior with a

hair dryer. After I was satisfied that it was dry inside I reinstalled

the tank and added fuel The sediment bowl and filter has stayed

clean and my fuel blockage problem was cured.

The engine was still not running properly. I drove the car to

Greg Solo's engine room because Greg asked to see it. He wasn't

there that day. When I went to start the TR to head home it would

not start. The plugs were not getting any spark. A check of the

points revealed that they were not opening. It turns out a brass

bushing holding the distributor shaft in place had worn so much

that the shaft had too much lateral movement to open the points.

I got a used distributor installed at the shop.

After the mechanic installed the distributor he made a quick

look at the DCOEs and determined that the idle circuits were not

working on three of the four venturis. One of the problems of

letting an engine sit with fuel in the lines.

I drove the TR home and cleaned all the jets, air correction

tubes and emulsion tubes. The inside passages were cleaned out

and air was blown through them. For being a very complicated carburetor

I'm amazed at how much work can be done on them without removing

them.

When I next fired up the engine the carbs worked a LOT better.

Unfortunately they were still running way to rich. The carbs are

way over jetted.

Oh did I mention that my new electric fan stopped working? I

checked the fan and isolated the problem to the sensor. I replaced

the sensor and control module and started driving the 3 on very

short trips.

A week later the starter motor bendex flew apart as I was trying

to start the car. This was a recently rebuilt starter motor. I

purchased it just so that I would have a good condition care free

motor. At least that was the theory. The motor was the newer type

with the bendex secured by a clip ring. The clip ring flew off

and most of the bendex parts ended up behind the flywheel, inaccessible

inside the bell housing.

So I decided to bight the bullet and had the car flat bedded

to Greg Solo's Engine Room. They removed the transmission and

the bendex parts. The DCOEs received some new jets and expert

tuning. The engine got a new distributor set up for mechanical

advance only. The new old starter motor was replaced by a new

geared starter motor that is a lot more powerful, smaller and

turns the motor faster. I had a number of little things done that

I had not gotten to yet. Less than a week after I had the TR towed

in I was able to place her on daily driver status.

I still need to hang a few more parts onto the car. I need to

get the assembly scratches painted over and replace the new chromed

parts that started rusting before the car became drivable. But

she is now on daily driver status. And I am learning to smile

again when I look at my TR3A.

After a few months I picked up a used TR3 fuel gauge at a British

car swap meet. So I now have a functional gauge.

I discovered a leak in the rear differential plate. The plate

had been damaged in the past and was slightly distorted near a

sealing surface. The damaged plate was replaced with a new Magnesium

plate that has much superior cooling and a larger diff oil capacity.

While I was replacing the differential cover, I noticed that

a steel hydraulic line was flattened where it ran along the front

side of the axle housing. When a car is loaded on a flatbed, they

place hooks at the rear (around my rear axle housings) and pull

the winch in to take out any slack in the chain/wires holding

the car on the flat bed. It looked like a hook was placed over

my rear brake line. I replaced that line and discovered that the

brakes work better if you use all four of them.

Fuel mileage has averaged 16 MPG with the DCOEs installed, and

the spark plugs have been fuel fouling at about 2000 miles. I

contacted Pierce manifolds and received jetting recommendations

for my engine. I purchased a set of new chokes, jets & emulsion

tubes and installed them. I was told that DCOEs needed low fuel

pressure in the neighborhood of 2 pounds pressure. Otherwise the

carbs would not run properly. I added a Holly fuel pressure regulator

and Russell fuel pressure gauge. As a result I discovered that

my fuel pump is putting out almost one pound of pressure maximum.

I rebuilt the fuel pump with a new kit.

At this point my TR3A is a quite dependable driver so I'm more

interested in driving it than working on it. As it's first winter

as a born again driver approached, I got the hood sticks refinished,

and installed them with all new straps and fixings. I added the

snaps to the new white hood and installed the door pockets for

the side curtains.

Checking the timing I discovered the resprung distributor is

advancing at 500 RPM. I've decided to bight the bullet one more

time and save up for a Mallory breakerless distributor. It is

designed to have the advance curve easily and exactly set. I still

need to replace my rusted new chrome parts and am collecting them.

This time as I collect them, I'm waxing them right away before

they go onto the TR3A. I'll break down and get the bumper and

overriders properly rechromed.

One of these days I hope to complete the rebuild.....

|

![]() TRIUMPH

Contents page > TeriAnn's TR3 rebuild project

TRIUMPH

Contents page > TeriAnn's TR3 rebuild project